Need more information?

We’d be happy to discuss our manufacturing capability offerings in greater detail with you. Please contact us at [email protected] or use our contact form.

Medical Tubing Solutions specializes in custom manufacturing of high-performance tubing for medical contract manufacturers. We provide a variety of innovative solutions to meet the needs of our customers in the cardiovascular peripheral, neuro space. We are committed to delivering value by developing innovative high-quality products quickly that perform the same every time.

We use our knowledge of tool design, process development and closed loop feedback controls to achieve tight tolerances by reducing long-term and short-term process variation.

Tolerances as low as +/- .00025″

In addition to single layer tubing, balloon tubing can be produced from a number of polymers. Balloon tubing typically has tight tolerance requirements as well as cosmetic and mechanical requirements; may be designed as a two or three layer design.

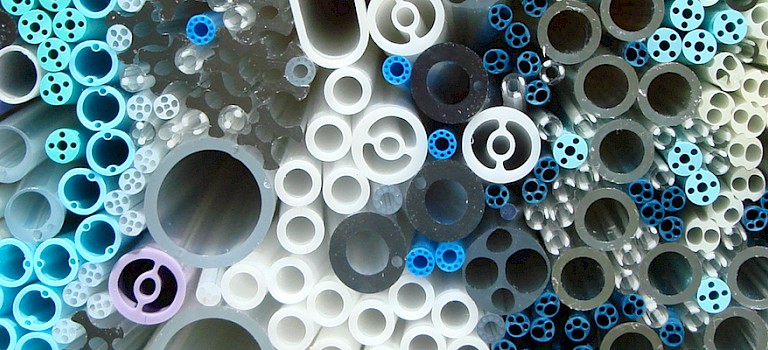

Multi-lumen extrusion is a type of tubing with two or more lumens that can be round or customized in shape. It is used for delivery of air, wire, fluids, sensors, and many other materials.

Reinforced Multi Lumen has an additional material type to allow advanced characteristics to tubing designs. The design can be customized to various shapes and material blends. It can be manufactured using various engineering thermoplastic resins and can also be extruded with an internal or external profile configuration.

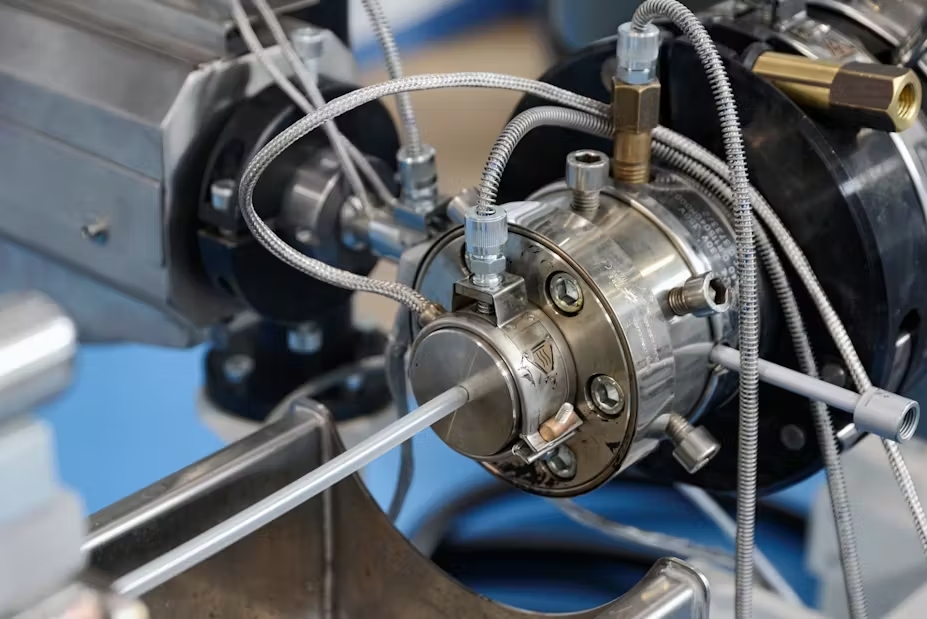

Overcoating can be performed on single-lumen, dual-lumen, and multi-lumen extrusion profiles. Some common overcoating’s include metal wires, braided shafts, monofilaments and other extrusions such as Acetal, PEEK, and substrate coated liners. Overcoating catheter liners can drastically reduce overall catheter cost by eliminating costly reflow operations.

Multi-lumen tubing has three or more lumens that can be round or customized with various shapes. It is commonly used to deliver air, fluids, or wires in medical and industrial applications. It can be manufactured using various engineering thermoplastic resins and can also be extruded with an external profile configuration.

Multi-lumen extrusions can also be extruded in an external profile configuration.

Monofilaments are often referred to as rod or beading. Monofilaments are solid round extrusions that can be manufactured out of virtually all thermoplastic polymers.

Monofilament diameters as low as .003″

Paratubing is made from two or more round tubes that have a thin web between them to hold them together. Paratubing is commonly referred to a peel apart tubing. Paratubing users require a set of tubes that are bonded together over their length but can be separated at different lengths for independent connectivity.

MTS uses proprietary tool design and processing techniques to produce precision micro diameter extrusions with outer diameters as low as .0025″ and inner diameters as low as 7.5 microns (0.0003″). MTS can produce the smallest inner diameter extrusions in the market, replacing more costly glass and stainless-steel alternatives. Micro diameter extrusions are available in single and multi-lumen configurations.

Common uses for micro inner diameters extrusions include drug delivery devices requiring ultra low and precise flow restriction.

MTS provides lead tubing with the highest levels of cosmetic clarity and dimensional stability. Urethane is a common thermoplastic polymer used for lead tubing. The urethane extrusion process requires a high level of understanding of polymer science and extrusion processing techniques MTS has many years of experience producing lead tubing to the highest standards.

At MTS, we use our knowledge of tool design, process development and closed loop feedback controls to achieve tight tolerances by reducing long-term and short-term process variation.

Tolerances as low as +/- .00025″

Co-extrusions can be comprised of two layers of separate polymer materials bonded together during the extrusion process, giving different desired physical characteristics on the internal and external surfaces.

Another common co-extrusion is a striped configuration using a primary polymer along with a secondary polymer added as a stripe or multiple stripes in different locations around the circumference of the extrusion. Stripes are commonly produced using radiopaque or colored polymers.

Co-extrusions can be comprised of two layers of separate polymer materials bonded together during the extrusion process, giving different desired physical characteristics on the internal and external surfaces.

Another common co-extrusion is a striped configuration using a primary polymer along with a secondary polymer added as a stripe or multiple stripes in different locations around the circumference of the extrusion. Stripes are commonly produced using radiopaque or colored polymers.

We’d be happy to discuss our manufacturing capability offerings in greater detail with you. Please contact us at [email protected] or use our contact form.